MEISEI R&D

Start R&D Projects with Innovation-oriented research and development

The headlamps, which are the face of the

automobile, and the rear combination

lamps, which accentuate the rear view,

are required to be more precise and

higher quality as the light source is

converted to LED.

We can help you "Design The Light"

with the microfabrication technology

and mirror polishing required for the

latest lamp parts such as

"LED light guides (light guide rods)" and

"LED thick-walled surface emitting lenses".

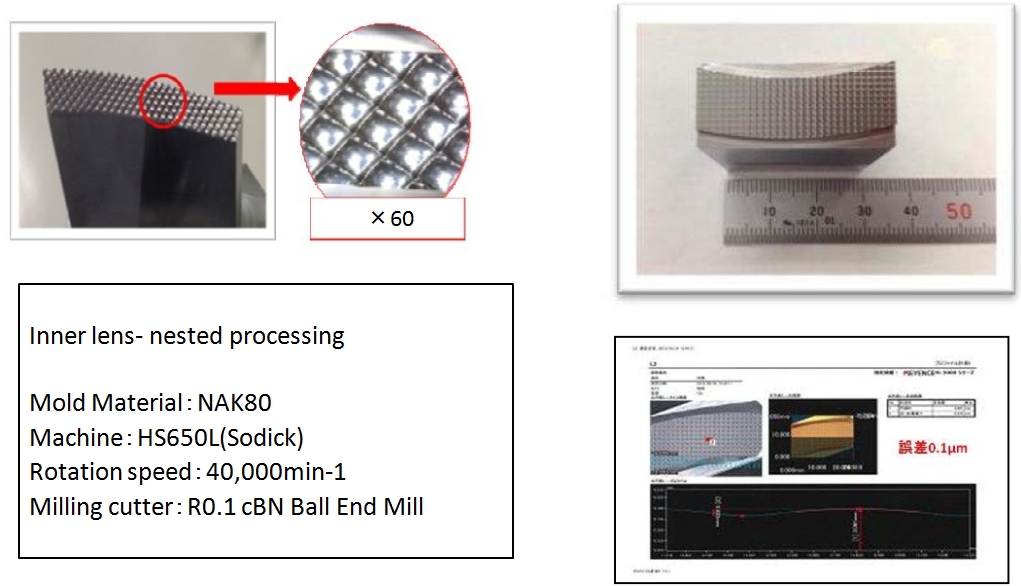

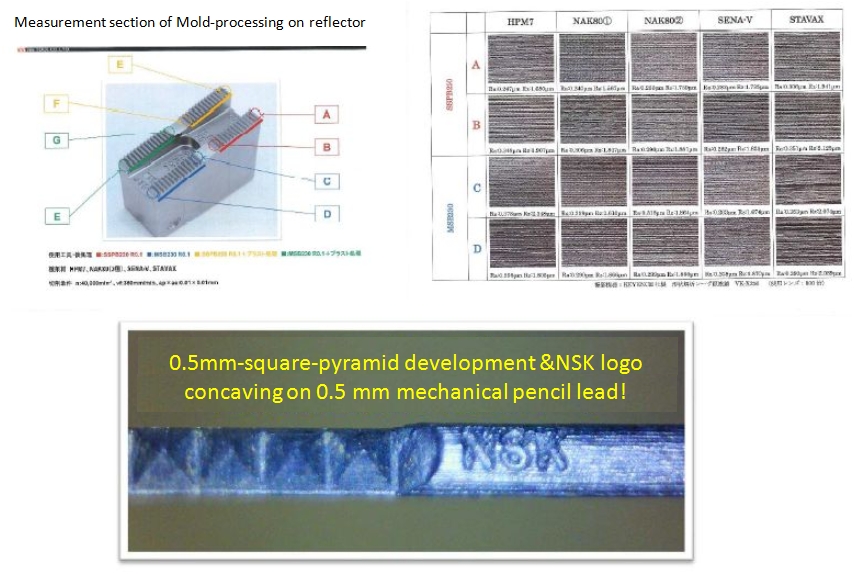

“Microfabrication”

—to achieve the light distribution intended by the designer

LED and laser light sources for automotive

lamps have a small light-emitting surface,

so it is essential to improve visibility

by diffusing the light. For this reason,

the lamps and reflectors require complex

lens cut surfaces.

At MEISEI, we use a linear motor

driven M/C to provide micromachining

with a minimum of R0.1 without grinding.

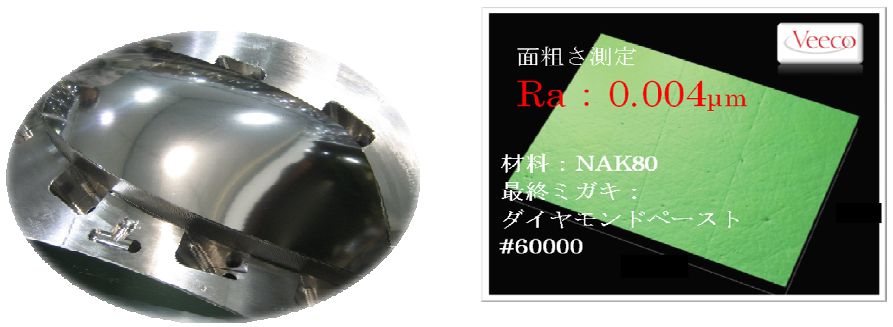

“Mirror Polishing”

— creates a high quality surface with no distortion and high transparency.

Large transparent lenses for automobile lamps

and large three-dimensional curved surfaces such

as aluminum direct evaporation products,

which require severe polishing, can be finished

into ultra-mirror surface molds using

high-precision NC machines and experienced

polishers.

Contents List

本社工場・技術管理本部

〒470-2102

愛知県知多郡東浦町大字

緒川字北鶴根66-5

TEL (0562)84-7600

FAX (0562)84-7644

熊本工場

〒869-1102

熊本県菊池郡菊陽町原水字

上大谷3802-32

TEL (096)233-9555

FAX (096)233-9556

宮崎工場

〒889-4222

宮崎県えびの市大字

小田1350

TEL (0984)35-2931

FAX (0984)35-2936