MEISEI Strengths

Our five domestic and overseas factories work together

to provide services from mold production

to after-sales service and follow-up.

Each of our production bases has functions such as sales, design, manufacturing,

and mold maintenance to not only meet the growing demand, but also to reduce the cost

and time required for mold transportation, respond quickly, and disperse the risk of disasters.

We have established a system to prevent defective products from being passed on to subsequent

processes by conducting inspections at each stage of the manufacturing process, while ensuring

the independence of the quality assurance department. We are promoting a "Reward System"

to promote continuous quality improvement by thoroughly evaluating each mold produced

and reflecting the results in the next mold.

The Automobile headlamps, which can be called the face of an automobile, and

the rear combination lamps, which accentuate the rear view, are important parts

in the design of an automobile, and the molds that realize their "Design"

require high technology that can fully reflect the intentions of the designer.

We specialize in "mirror polishing" to create a high quality surface with no

distortion and high transparency, "microfabrication" to secure the necessary

light distribution, and various reliable "slide mechanisms" for undercut processing.

Since 2011, we have been accepting employees from overseas bases to our Japan plant for training

in order to improve their technical capabilities and strengthen cooperation.

This system fosters global employees who can not only collaborate with each other but also respond

to customers' requests for overseas business trips by using the skills and Japanese language

acquired through the practical training.

A caring trainer

Here is a cue

You have good hands!

Based on the philosophy that "manufacturing is human resource development,"

we focus on developing "people who can think and act on their own" through

external training programs for each level, departmental policy activities for managers,

QC activities for groups, and an improvement proposal system in which all employees participate.

We also conduct aptitude tests for all employees as an activity to maximize their

abilities and propose an environment where the right person can work in the right place.

◆Partnership:

Ise Mold Industry Co. ltd, (Mie)

MS Seisakusho Co. ltd, (Aichi)

NSK (Nagoya Precision Mold, Co, ltd) (Aichi)

Business Innovation Partners; A consulting agency in Tokyo

With this global partnership agreement, 3 mold-manufacturing corporations’ overseas branches will work together to satisfy customers’ needs more promptly.

Chubu Economy Newspaper on March 3

-“Partnership: Team work for Mold repair beyond Japan

4 corporations; 3 Manufacturing Corporations in Chubu and 1 consulting agency from Tokyo New Business Model Proposal -

Daily Industry Press on March 5

-3 allies -Mold-Manufacturing Corporations’ Partnership Agreement

Techno-Team-working: Complementary Networking for Mold Production and

Repair in domestic/international venue among allied Partners-

With 50%chance of success, it was a hallmark of the corporate milestone, that NSK was certified as AICHI QUALITY COMPANY in 2018.

【Highly-evaluated theme : ‘Integrated challenge of Advancing Mold-processing skills” and Meister technique of ‘Mirror Polishing’ by hand-sensing-finish】

As gleaming designated corporations to boost Aichi prefecture, Japan’s “Manufacturing Kingdom” , NSK, with a sense of pride and esteem in engineering skills, shall challenge further development in global communities.

◆AICHI QUALITY COMPANY

Under the direction of their top leadership and outstanding company philosophy, these manufacturers continue to innovate their business process and leverage their unique strengths. These companies have considerations for the environment and work to generate customer equity by creating a customer-first brand.

Picture of Certified formula

Mr.Nanya,President & Mr.Omura, Aichi Governor

Sample for 'mirror polishing'

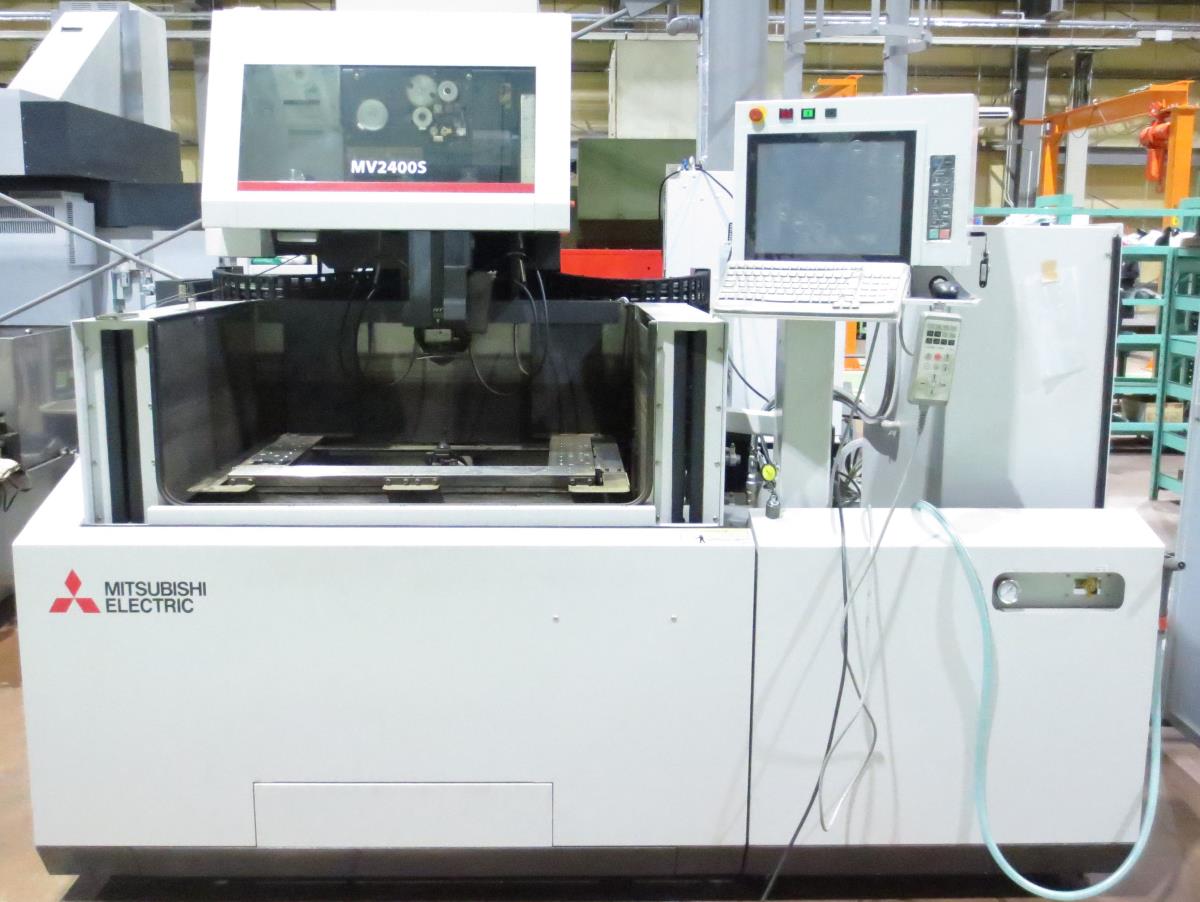

三菱電機 ワイヤ放電加工機 MV2400S

最大ワーク寸法:1050×800×295

最大積載量:1500kg

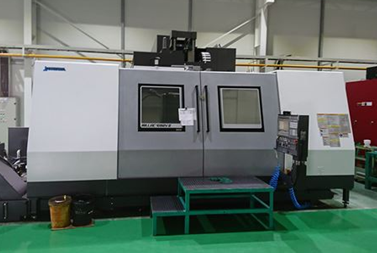

牧野フライス 5軸立型マシニングセンタ D800Z

移動量:1200(X)x1100(Y)x650(Z)

-93゜~0゜(B軸) 360゜(C軸)

テーブル面の大きさ:φ800

最大ワーク寸法(直径x高さ):φ1000x550㎜

最大積載重量:1200㎏

主軸回転速度:50~14000rpm

工具収納本数:40本

その他設備は、コチラからご確認ください。

工場見学

ミガキ体験

名刺交換

くまモン名刺(表)

くまモン名刺(裏)

①3次元測定器(CMM)

Global advantage12.15.10

X=1200㎜,Y=1500㎜,Z=1000㎜

②大型マシニングセンター

DCV2012B

X=2000㎜,Y=1200㎜,Z=762㎜

その他設備は、コチラからご確認ください。

東浦知多インター側

巽ヶ丘駅側

三菱電機ワイヤーカット MV2400Sコラムアップ仕様

□用途:ワイヤ放電加工機

□機械グレード:高生産性機

□機械サイズ:中形機

□シリーズ:MV-Sシリーズ

□形名:MV2400S(コラムアップ仕様)

□最大加工物寸法:1050mm×820mm420mm

□工作物許容質量:1500kg

□テーブル寸法:840mm×640mm

□各軸移動量:600mm×400mm×425mm

□外形寸法:2837mm×3030mm×2380mm

□機械本体質量:3650kg

□加工槽扉:全面自動昇降扉

牧野フライス 立型マシニングセンタ V77L

テーブルサイズ(mm):1650X700

最大積載重量(Kg):2000

ファナック ロボドリル α-D14MiB5

テーブルサイズ(mm):650X400

最大積載重量(Kg):300

三起精工 ダイスポッティングマシン

SDP-2015-200

テーブルサイズ(mm):2000X1500

加圧能力(KN):2000

デーライト(mm):1700

最大積載重量(Kg):15000

MICRONTEC ガンドリル GD-1200 H/NC

テーブルサイズ(mm):800X1400

MAX.DEPTH(mm):1000

最大積載重量(Kg):5000

三菱電機 放電加工機 EA40M-ADVANCE

工作物最大寸法(mm):1900X1100X600

最大積載重量(Kg):5000

平成27年 現代の名工 表彰式

【1】工場の外観

【敷地面積】:8,160㎡ 【事務所棟】:815㎡ 【工場棟】:1,605㎡

事務所棟外観

工場棟外観

①クレーン重量:最大15t完備

15t/7t親子クレーン1基

7tクレーン3基の計4基

②鏡面ミガキ専用ミガキ室の設置

③空調管理下での微細加工専用加工室設置

④直線ラインを保持した機械専属棟

8月末に工場が完成しました

【新工場面積】 1240㎡

【機械設置】 10月中旬~下旬

【稼働開始】 11月~

【新設機械】 OKKマシニングセンタ、オークママシニングセンタ、ガンドリル、ダイスポッティング

【加工可能サイズ】 4輪金型(HLレンズ、ハウジング、ケース等)、

アルミダイキャスト金型(2輪のホイール型)

Contents List

本社工場・技術管理本部

〒470-2102

愛知県知多郡東浦町大字

緒川字北鶴根66-5

TEL (0562)84-7600

FAX (0562)84-7644

熊本工場

〒869-1102

熊本県菊池郡菊陽町原水字

上大谷3802-32

TEL (096)233-9555

FAX (096)233-9556

宮崎工場

〒889-4222

宮崎県えびの市大字

小田1350

TEL (0984)35-2931

FAX (0984)35-2936